How To Change The Rubby Seal Around Whirl Pool Dryer Door

Whirlpool Dryer Seals and Gaskets

Detect your role

Enter your model number or a office number and click "Search"

Hither is an example model number plate:

Pop Whirlpool Dryer Seals and Gaskets

Rear Drum Felt Seal

PartSelect Number PS8691753

Manufacturer Part Number W10612022

This seals Includes adhesive. This part helps seal the pulsate to prevent hot air from escaping.

Fixes these symptoms

- Marks left on clothes

- No heat or not enough rut

- Noisy

- See more...

Installation Instructions

Paul from Monmouth, IL

intermittant heat

First I shut off the gas supply and disconnected the dryer vent and unpluged the unit so you can admission the rear of the dryer. So I removed the rear comprehend. This is where you will discover your thermostats and fuses. Holding the new part next to the one to be replaced I transfer the wires ane at a time and so as not to get them mixed up, so unscrew the old function and install the new one. Insert a apartment bract screwdriver under the top encompass in the 2 front corners to unsnap it from it'due south clips, also at this fourth dimension you need to remove the 2 screws that agree the upper part of the lint filter tube to the lid, and so elevator the chapeau to expose the pulsate ( I tilted the dryer dorsum equally far as the flex gas line would allow me to and rested the meridian lid against the wall without removing information technology, to many wires). Behind the front cover in the meridian right corner is the plug for the door switch,un-plug it and also at that place are 2 screws one in each corner. Later that lift the front cover straight up and pull information technology away from the cabinet ( information technology has clips at the lesser to hold it in identify). Reaching under the pulsate on the right side pull down on the belt tensioner and release the belt from the motor then you lot can remove the drum. Laying the drum down on it's front edge I removed the rear felt seal and took a piece of sand newspaper to crude up th sometime glue and clean off some of the felt that was nevertheless stuck to the drum. Post-obit the directions from the seal package I put the glue around the border of the drum and re-installed the new felt. This is a good time to clean out your dryer, while the glue sets up. A shop vac works the all-time, simply be carefull not to suck upward the money, it will help pay for the repair ( I institute over a dollar in modify ). At this time I also changed the coils on the gas valve, remove the ii screws that hold the clench and replace them i at a time. Re-install the drum with the belt on it, fold it and push it through the tensioner and put it on the motor pulley. rotate the drum to make sure that the felt is non kinked under itself, re-install the front cover bottom clips first, and then the two screws and the plug for the door switch, pull downwards the hat and snap it in place, earlier installing the rear embrace this is a good fourth dimension to remove the rear cover to the lint chute and clean in there too ( it's like shooting fish in a barrel to come across why in that location are and then many dryer fires). Re- install that embrace and the rear cover and vent tube, plow your gas back on and bank check it for leaks ( even if you didn't disconnect it) plug your dryer dorsum in and go busy catching up on the laundry that yous haven't had a chance to do considering your dryer bankrupt, and then grinning and call up near all the money yous saved past doing this unproblematic repair your cocky. Thank you Parts Select Read more...

Door Gasket

PartSelect Number PS11731610

Manufacturer Part Number W10861521

This door seal does non include the agglutinative gum.

Fixes these symptoms

- Door won't close

- Marks left on clothes

- No heat or not enough heat

- Meet more than...

Installation Instructions

Manolak from MURFREESBORO, TN

Door Gasket tore out

Put loftier temperature glue on first, and then put door gasket over the high temperature glue so permit it set for 24 hours. It worked fine.... Read more...

Lint Trap Housing Seal

PartSelect Number PS11741506

Manufacturer Office Number WP339956

This is foam seal for your dryer. Information technology forms a seal to prevent air from escaping the rear of the dryer pulsate and the lint duct. This model comes with adhesive bankroll and is located in between the lint chute and the bulkhead of your appliance. This foam seal is but over 28 inches long and under 1 inch broad. You lot may demand to replace this part if your clothing is taking too long to dry, or if your dryer is not generating enough heat or no rut at all.

Fixes these symptoms

- No oestrus or not plenty heat

- Noisy

- Takes too long to dry

- Run into more...

Installation Instructions

Eric from Fort Contrivance, IA

dryer drum not turning and no air circulating

replaced motor and pulsate rear seal every bit well as idler wheels, the old rear pulsate seal was completly worn out, since I had it all apart, I replaced lint chute and trap seals and chugalug and tensioner. I spent less money on parts than if I would have bought a new dryer. The motor was the main problem as the bearings were shot. Read more...

Dryer Drum Seal with Agglutinative

PartSelect Number PS970088

Manufacturer Part Number 280114

This drum seal with a silicone rubber adhesive is used in dryers. This part seals the drum to make certain air does not escape from the dryer. If your dryer is making loud noises, is not producing enough heat, or no heat at all, or there are marks left on your wearing apparel, replacing the seal on your dryer tin solve the problem. The tools needed for this installation project are: i/four inch nut driver, Phillips screwdriver, small apartment blade screwdriver, and putty pocketknife. Think to unplug your dryer from the ability source earlier beginning this installation project. Refer to the manual provided by the manufacturer for installation instructions.

Fixes these symptoms

- Marks left on clothes

- No heat or not enough estrus

- Noisy

- Run across more...

Installation Instructions

Jerry from Everett, WA

Rear tub seal failure

I removed the height cover and so the back cover, released the belt tensioner and removed the drive belt. Then slid the tub out of the unit and onto the back dack. Sanded the remnents of the old seal off. Wiped the tub lip with laquer thinner and practical the "fast" drying glue supplied with the kit. Installed the seal and re-assembled the unit...works fine Read more...

SEAL-DOOR

PartSelect Number PS11766744

Manufacturer Part Number W10906683

Fixes these symptoms

- No heat or not enough heat

- Takes too long to dry

- See more...

Installation Instructions

alice from wickliffe, OH

seal came of dryer door

romoved from pkg. and fit it to the door. no tools needed. all-time of all the office came in 24 hrs and was stock-still with out filibuster of waiting from a store that was out of our surface area. great costumer service!!!!! Read more than...

Seal, Inner Cap

PartSelect Number PS11748108

Manufacturer Part Number WPW10072840

This is an inner cap seal, just may also be known every bit an O-ring, and information technology is a function for your washing machine. Some symptoms replacing this role will ready include: leaking from your appliance, uncontrollable shaking and moving, loud noise, pumps but will not spin, or if your apparatus will not agitate. This model is off-blackness in color and 3 inches in bore. You volition find this role inside the anarchist in the centre of your washing car. It is recommended to wipe downwardly the barrier earlier putting the new seal on.

Fixes these symptoms

- Does not manipulate fabric softener or detergent

- Leaking

- Noisy

- Come across more...

Installation Instructions

Lennis from Jacksonville, NC

Would non agita.

It was a approving that I ordered the kit, considering I thought it only needed the condom seal and the four dogs. Simply because the seal and dogs toll less than the shipping I decided to gild the kit and its good I did because the nochage on the basket sleeve was bankrupt off. The blessing is that the sleeve was in the kit, sp it took 5 sec to sideslip it on along with the rest of the kit, and after about 15 min my wife was back to piece of work. Thanks for saving me time and coin without this web site I would have bought another brand new washer, thanks. Lennis from NC. Read more...

Door Glass Seal

PartSelect Number PS12114459

Manufacturer Part Number W11126230

Seal and Bearing

PartSelect Number PS11773177

Manufacturer Part Number W11035878

This front panel seal kit doesn't include the plastic retainers, reuse the old retainers. No glue is needed, the seal stretches to fit.

Fixes these symptoms

- Marks left on clothes

- Noisy

- Takes too long to dry

- See more than...

Installation Instructions

Stephen from Springfield, MA

Dryer making loud squealing noise when running

The (front) bearing and seal are not metallic parts but a textile and and mesh similar material. It is somewhat like a material belt made to agree up a pair of trousers. The belt sits in a channel that goes around the door on the within of the front console. To get to the combination begetting/seal y'all remove two screws that are located nether the embrace of the lint trap. These accept to exist removed to lift the height. Then using a putty pocketknife or screw commuter you must pop the peak (which snaps downwards on plastic clips) at the forepart corners. The top lifts upwardly and folds back on hinges. The front is fastened to the sides by one screw on each side near the pinnacle. A nut commuter will remove and then easily. One time the 2 screws are removed lift the front panel about 2 inches to undo the front end console from the clips that concord the front attached to the sides near the bottom. When you remove the forepart panel the dryer drum will literally fall out so y'all want to get agree of it before pulling the front end panel abroad so information technology isn't damaged and and doesn't impairment the gas burner assembly which is under the pulsate to the left side. The drum is very light. I supported it with an empty shoe box while the front was off. I likewise did the rear dryer seal. This is similar to the forepart. To do this you follow the procedure higher up but to get to the real seal you will have to remove the drum. It will fall out on its own if the front panel is removed. The drive belt goes around the drum. It is about iii/8th of and wide and but wraps around the drum without any teeth or channels or anything. Let the belt fall to the bottom as you elevator the drum forward and out of the cabinet. The drum is light. Just put information technology on the floor and strip off the old rear seal which is glued on. It too is fabric. Make clean up the drum a little and fit the new seal on the drum. Once the seal is on the pulsate you can lift the border of the fabric seal and glue the fabric flange to the drum. This becomes pretty obvious in one case you take the seal on the pulsate. If y'all put the mucilage on the drum first you will make a mess. Put the seal on properly and the lift the edge to utilise the adhesive all the manner around. The adhesive sets enough in a hour or so. Put the drum back in and replace the forepart panel. Don't forget the drive chugalug. It goes effectually the bulldoze motor that is located on the bottom of the dryer on the correct, around or over an idler pulley (my older model does not take a idler wheel but rather a bracket with a "slide" that the belt runs over that keeps sufficient tension on the belt to bulldoze the drum. If your belt falls off the motor and the idler pulley falls out information technology may be disruptive how the belt goes in. My idler subclass is held in slots on the bottom of the cabinet merely by the tension of the belt - no screws or anything. I advise that you put the belt effectually the drum commencement, so the bulldoze motor. You volition have slack in the belt and information technology becomes a little more obvious how the idler pulley (which is mounted on spring steel) goes in and takes up that slack and keeps modest tension on the belt. The rubber side of the belt goes confronting the drum, the leathery side is the outside.

Once the front is off you'll see the bearing/seal on the inside of the front panel and it will be obvious how to remove the old one and identify the new 1. In that location are iii pegs on the front end panel that receive the three holes in the textile begetting/seal. The seal will stay in place while you remove the shoe box and put the front comprehend back on. The drum fits over the seal like a chapeau on a jar and merely slides on the textile when the drum rotates. Low tech merely the drums slides hands on the bearing material and seems to terminal a long time.

Door Seal with Agglutinative

PartSelect Number PS2349140

Manufacturer Part Number W10239307

This part creates a seal effectually the door. High temperature adhesive is included.

Fixes these symptoms

- Door won't shut

- Takes too long to dry

- See more...

Installation Instructions

Janet from LOS ANGELES, CA

The seal came off our dryer door.

Take door off dryer (unscrew four screws). Lay door on flat surface. Using mucilage provided glue down new seal. Put dryer door dorsum on and you're done! Read more...

Blower Housing Seal

PartSelect Number PS11743810

Manufacturer Part Number WP697770

This part seals between the blower housing and the blower housing embrace.

Fixes these symptoms

- No estrus or not plenty rut

- Noisy

- Run into more...

Installation Instructions

Boonkham from SMYRNA, TN

Related Parts

- All Whirlpool Dryer parts

- Whirlpool Dryer Belts

- Whirlpool Dryer Brackets and Flanges

- Whirlpool Dryer Caps and Lids

- Whirlpool Dryer Circuit Boards and Bear on Pads

- Whirlpool Dryer Doors

- Whirlpool Dryer Drums and Tubs

- Whirlpool Dryer Ducts and Vents

- Whirlpool Dryer Elements and Burners

- Whirlpool Dryer Filters

- Whirlpool Dryer Fuses

- Whirlpool Dryer Handles

- Whirlpool Dryer Hardware

- Whirlpool Dryer Hinges

- Whirlpool Dryer Hoses and Tubes

- Whirlpool Dryer Knobs

- Whirlpool Dryer Latches

- Whirlpool Dryer Lights and Bulbs

- Whirlpool Dryer Panels

- Whirlpool Dryer Pulleys

- Whirlpool Dryer Sensors

- Whirlpool Dryer Springs and Stupor Absorbers

- Whirlpool Dryer Switches

- Whirlpool Dryer Thermostats

- Whirlpool Dryer Timers

- Whirlpool Dryer Trims

- Whirlpool Dryer Valves

- Whirlpool Dryer Wheels and Rollers

- Whirlpool Dryer Wire Plugs and Connectors

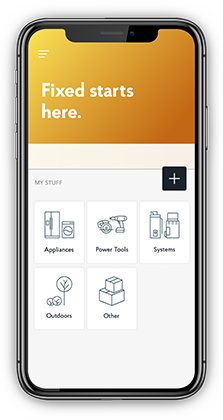

Taking the guesswork out of your repairs

With our Fix app model plate paradigm recognition technology, we'll recommend the parts guaranteed to fit your appliance. Simply snap a photo, and we'll accept care of the rest.

Source: https://www.partselect.com/Whirlpool-Dryer-Seals-and-Gaskets.htm

Posted by: shillingsponforsittle.blogspot.com

0 Response to "How To Change The Rubby Seal Around Whirl Pool Dryer Door"

Post a Comment